Units We Clean

It's a dirty job, but someone's got to do it. Bring us your challenge, our team of experts will engineer a solution.

We continue to raise the bar. Our experience is unmatched and our customized approach is unique. Our successes in decontamination and cleaning are known worldwide. When you work with us, you'll experience the ZymeFlow difference.

For Every Unit, We Have A Unique Solution

Heavy Oil

Sour and heavy crude processing typically results in significant deposits and high percentages of contaminants. Fortunately, we're the experts in decontaminating this type of equipment efficiently and effectively worldwide. Our custom solutions and proprietary chemistry save time while reducing, or even eliminating, the need for mechanical cleaning.

Hydrotreater/Hydrocracker

ZymeFlow boasts innovative chemistries and applications to effectively clean all parts of hydrotreaters and hydrocrackers – which typically include hydrogen sulfide, iron sulfide, and potentially immense amounts of ammonia. Our multidisciplinary team has decades of experience eliminating these challenges around the world.

Amine and Caustic Treating

Amine and Caustic Treating units present unique challenges; our experts understand what it takes to handle the job. Customers worldwide count on us for our targeted approach to these engagements. In fact, our cleaning process is so well respected that it's included as a best practice by several well-known equipment and technology providers.

Light Ends

These units don't typically experience heavy fouling or sludge build up, but they still need to be cleared of benzene and LEL before entry or maintenance. Our innovative chemistry and approach does just that but in a fraction of the time.

Chemical Processes

Each specific unit in chemical processing requires a custom, dynamic decontamination solution. This is where we put our years of expertise to work for you. Our experienced team employs the appropriate chemistries and application methods required to give you the best results.

Olefinic Processes

ZymeFlow has years of experience in cleaning some of the largest olefin plants in the world. Our team understands that issues vary drastically depending on each plant. From heavy coke deposits to high levels of benzene, our experts plan and execute the best approach for fast and safe entry.

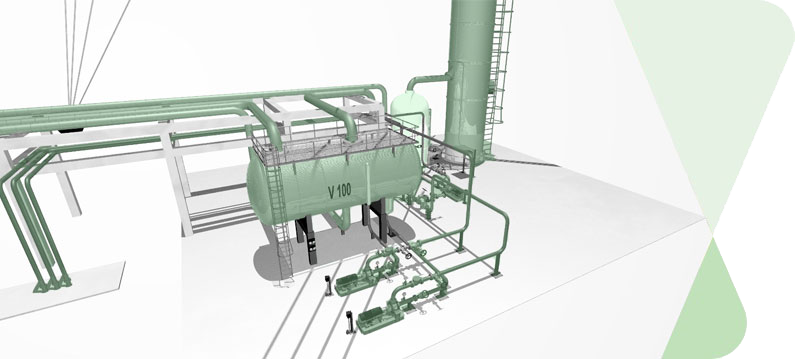

Other Refinery Components

Our team has the proven global knowledge, innovative chemistries and more than 30 years of experience to carry out the cleaning of all refinery components. That experience includes not only major equipment but also more unique components from flare systems to pipelines. That's why you can turn to ZymeFlow for a complete turnkey solution.

Let's get started.

Our team has the proven global knowledge, innovative chemistries and more than 30 years of experience to carry out the cleaning of all refinery components. That experience includes not only major equipment but also more unique components from flare systems to pipelines. That's why you can turn to ZymeFlow for a complete turnkey solution.